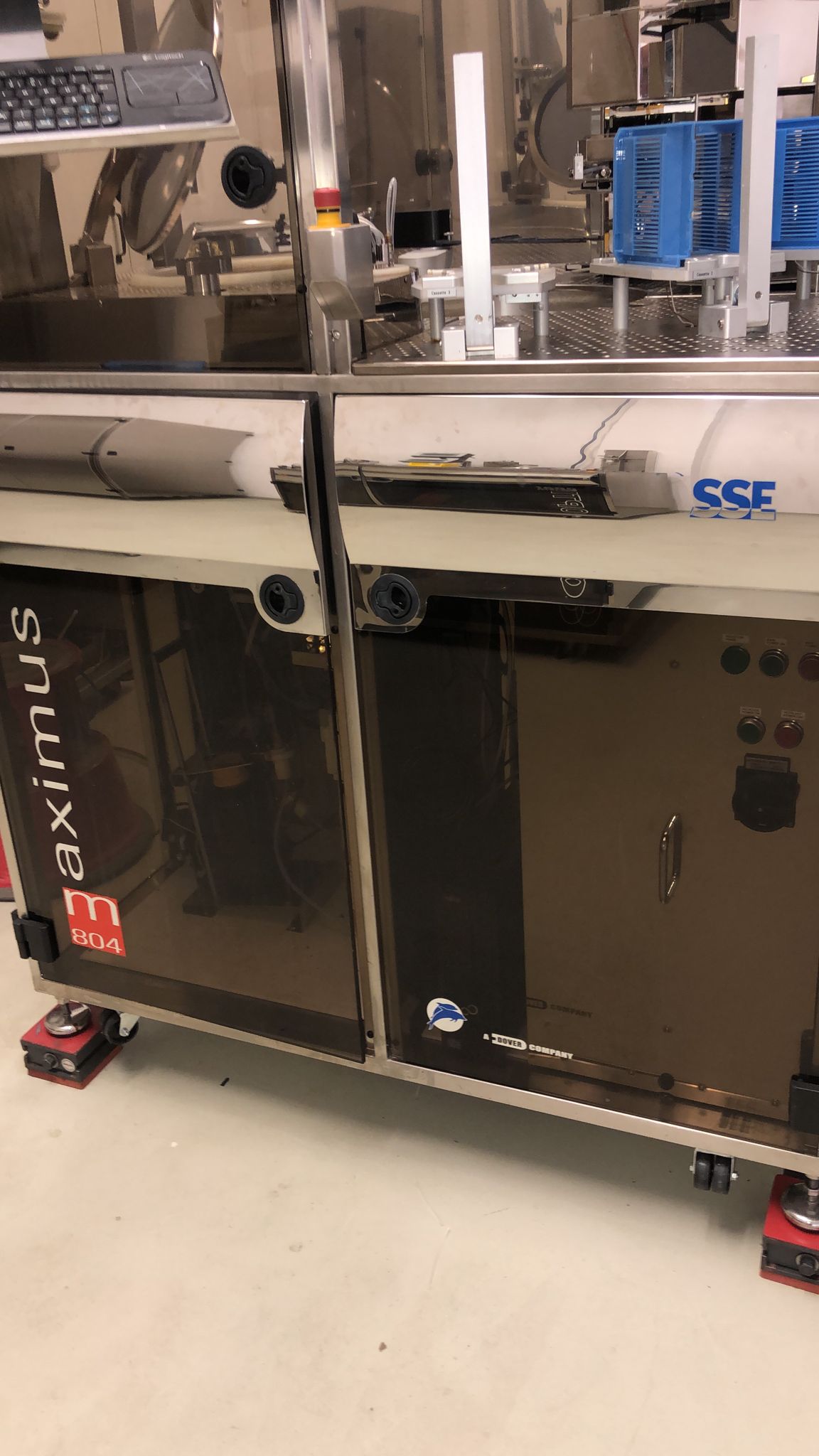

SSE Maximus Single Coater Closed Cover Chuck with max. 4 Hotplates and 1 Coolplate.

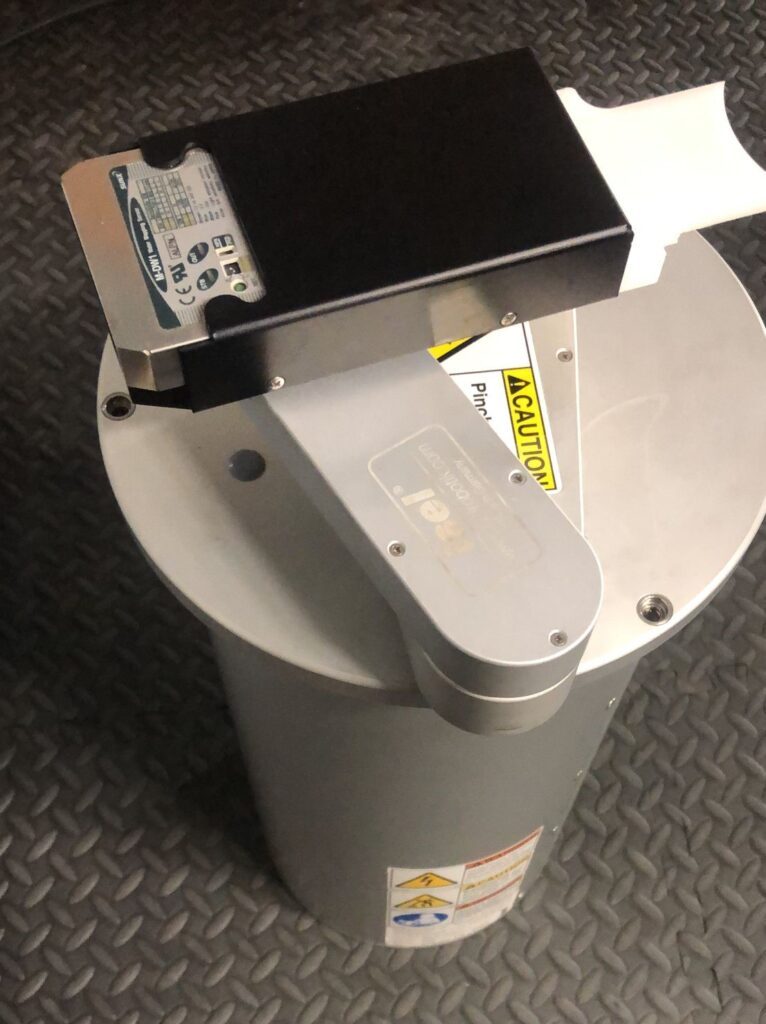

For sale: Here is an ISEL IWH-TA10S10F-1 Wafer Handler manufactured in 2009.

The robot is fully functional and comes with the pictured mapping sensor. As the robot comes from a Siconnex Vertical Developer, we also have a corresponding guide rail and controller. The robot has been in use for around 4 years in total. The robot was taken out of production in 2018. The robot is in excellent condtion.

The robot is immediately available. If you have any questions, please feel free to contact us: Cell number:

+49 170 2844435

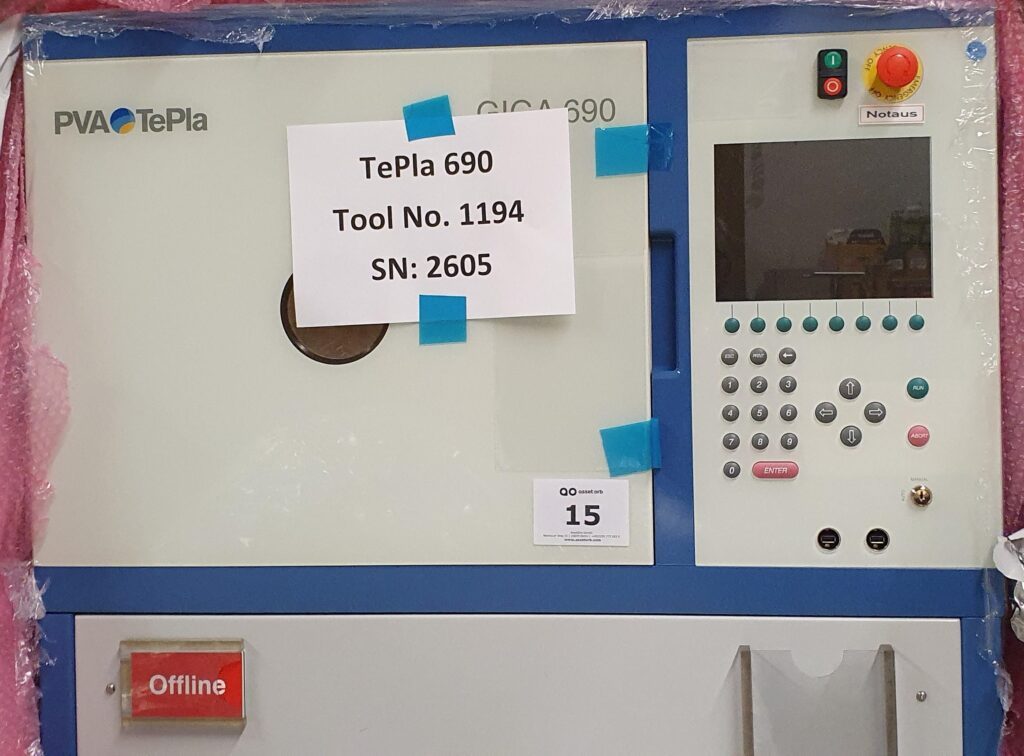

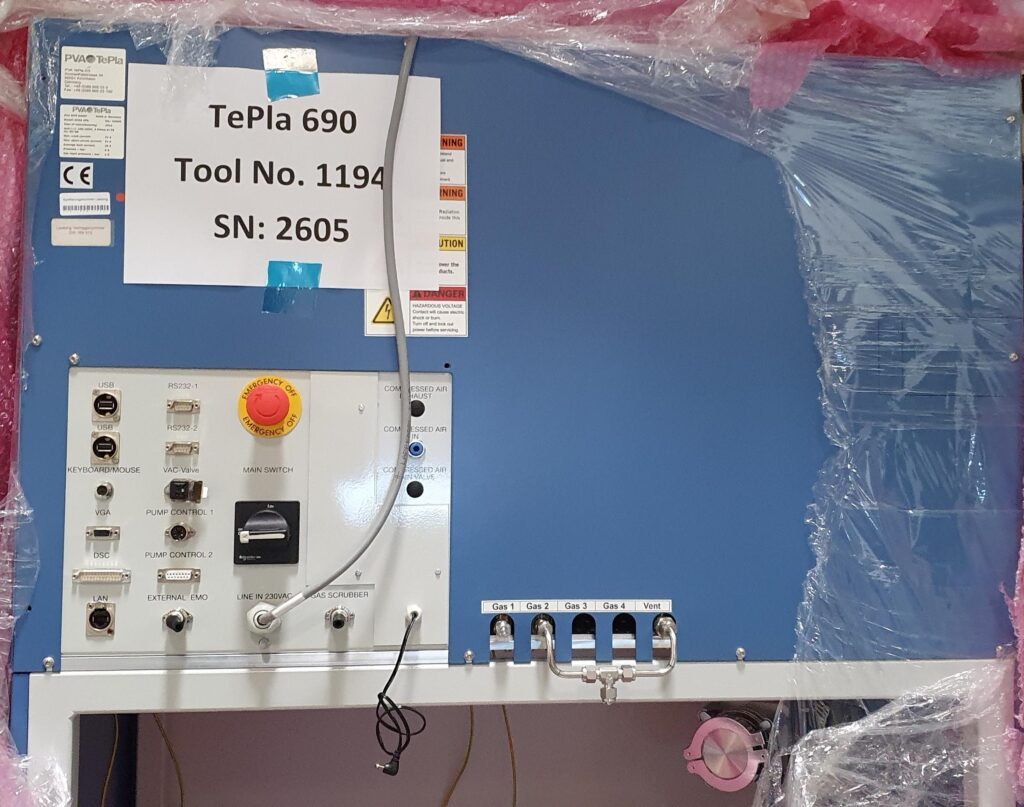

We are selling here a GIGA 690 from PVA TePLA.

The GIGA 690 is a MICROWAVE PLASMA SYSTEM. Further information:

The GIGA 690 was 4 years in production and is in a realy good condition. Year of manuafcture mid 2015 and taken out of production in early 2019.

The Machine is currently crated as can be seen, but can easily be prepared for inspection. The location is in Germany. For further information please contact us.

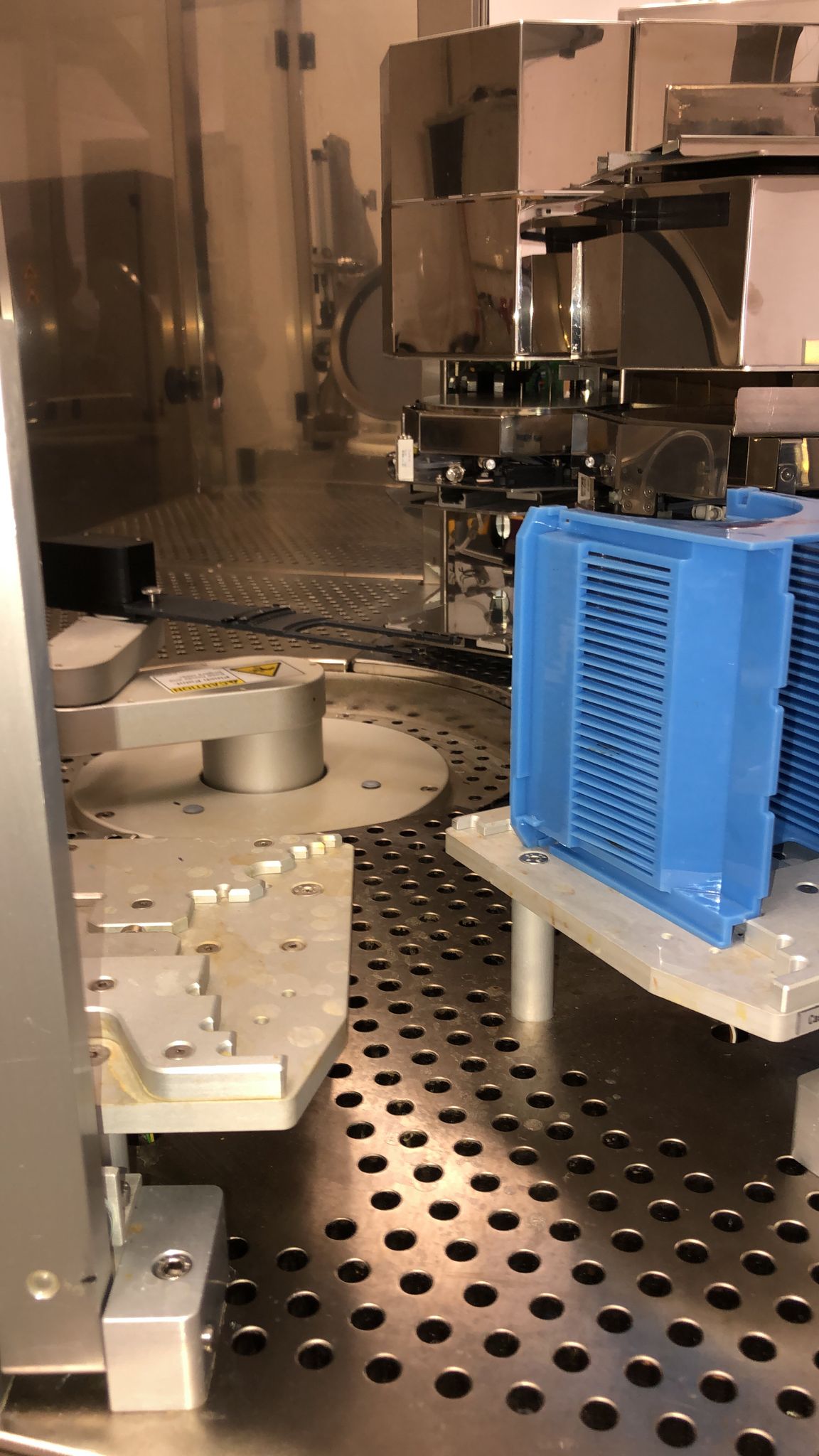

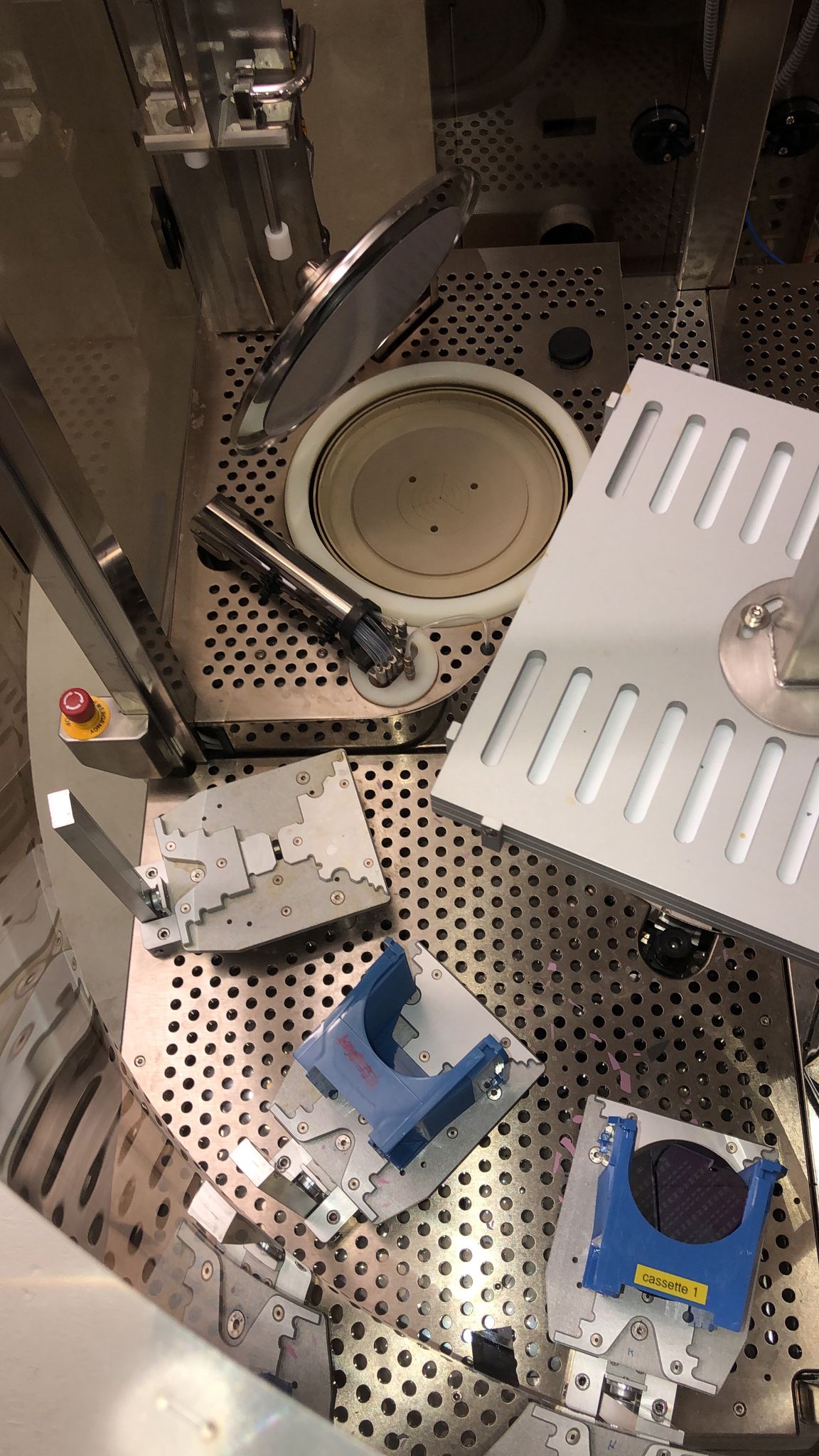

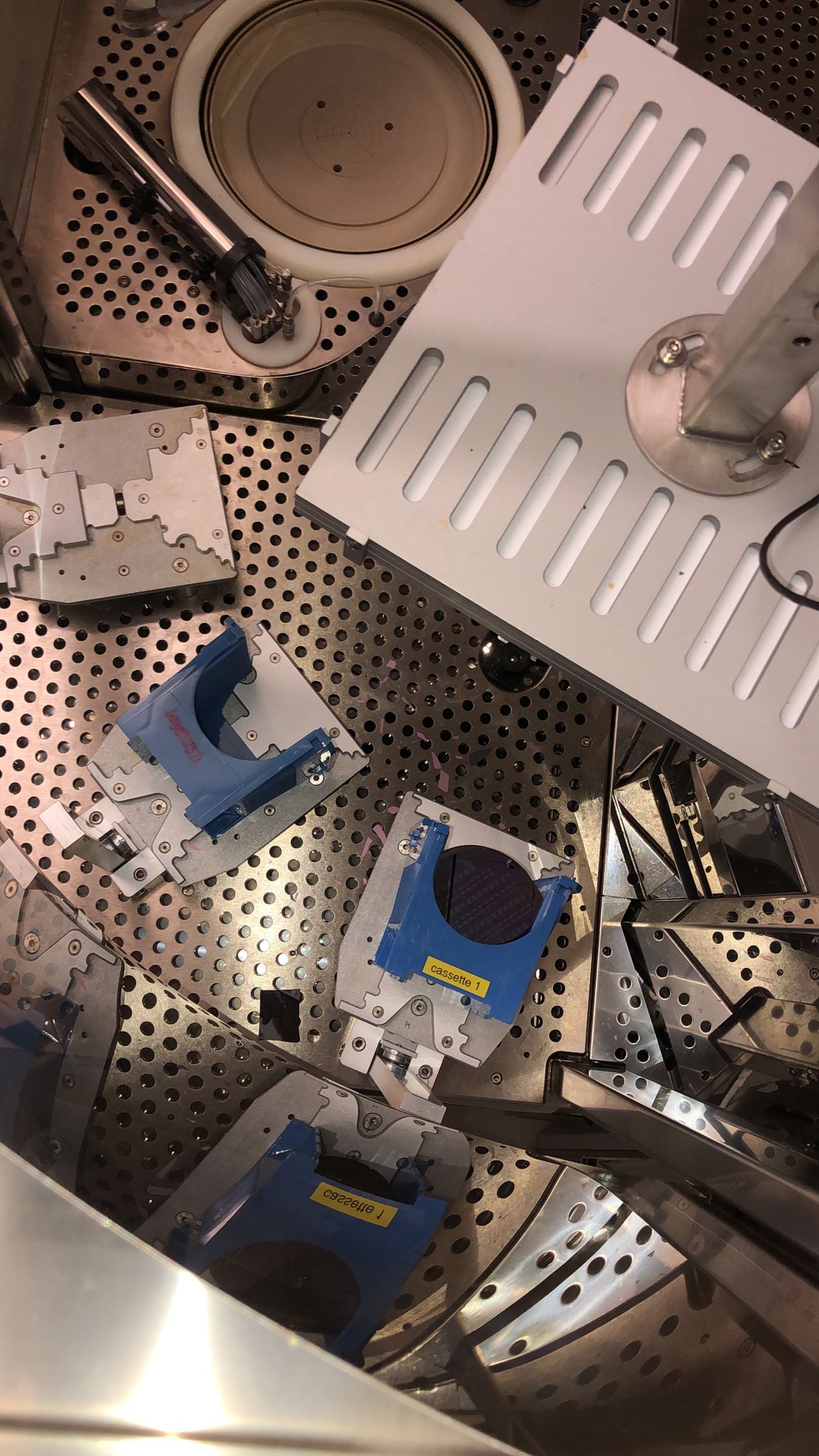

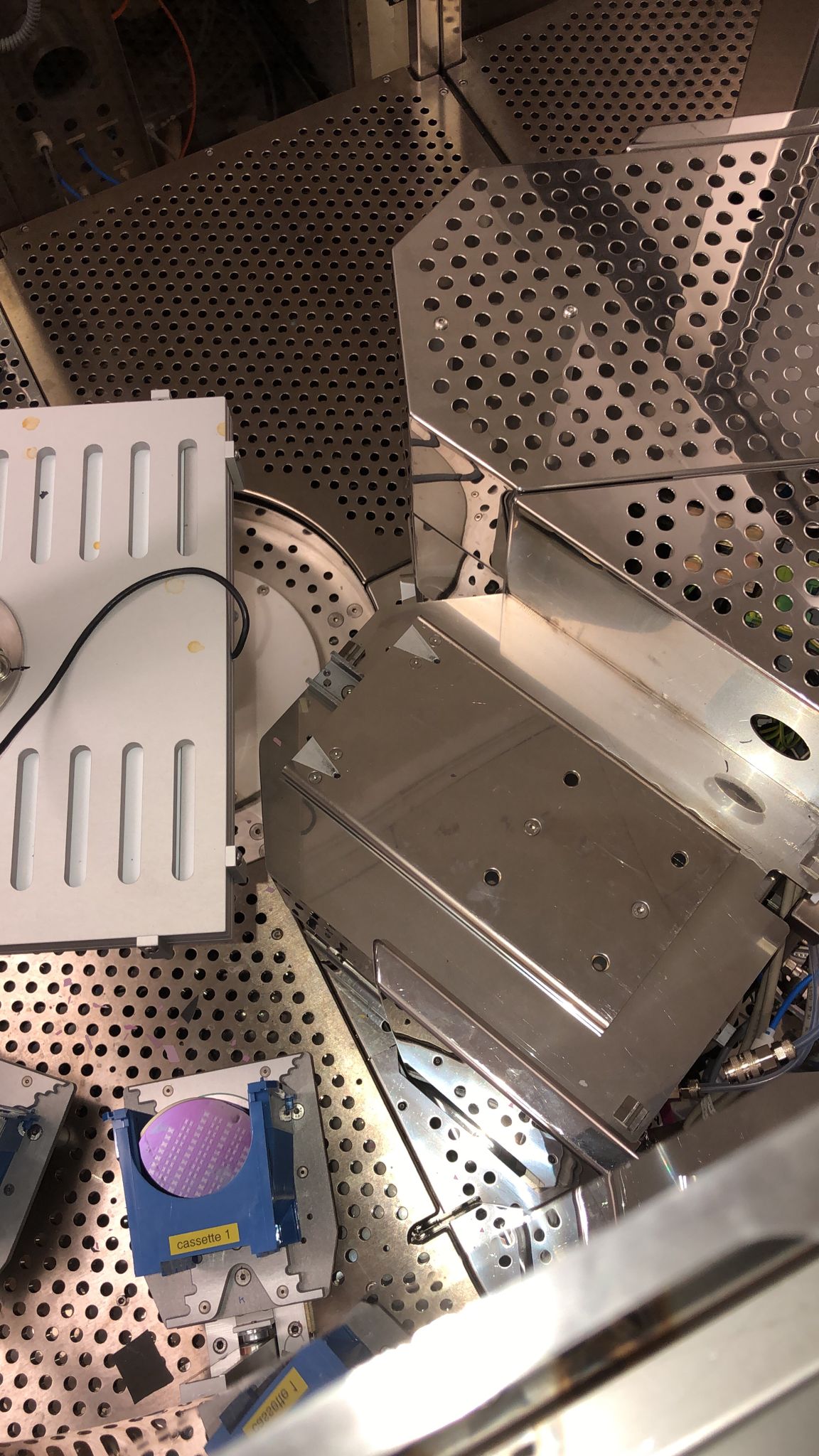

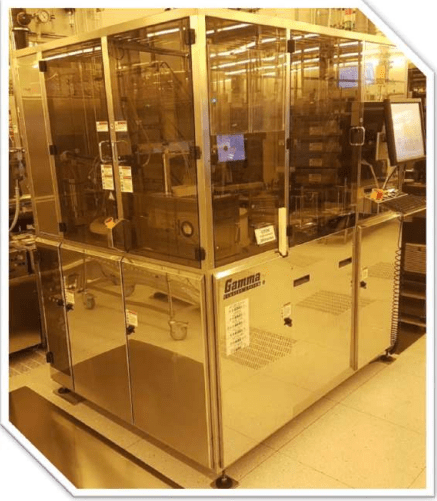

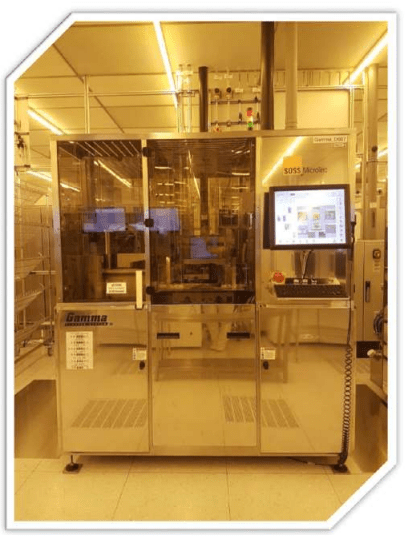

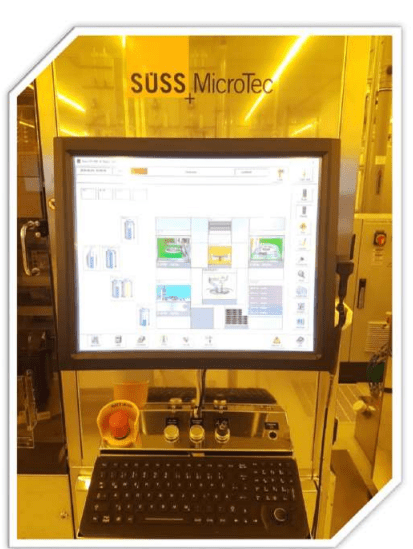

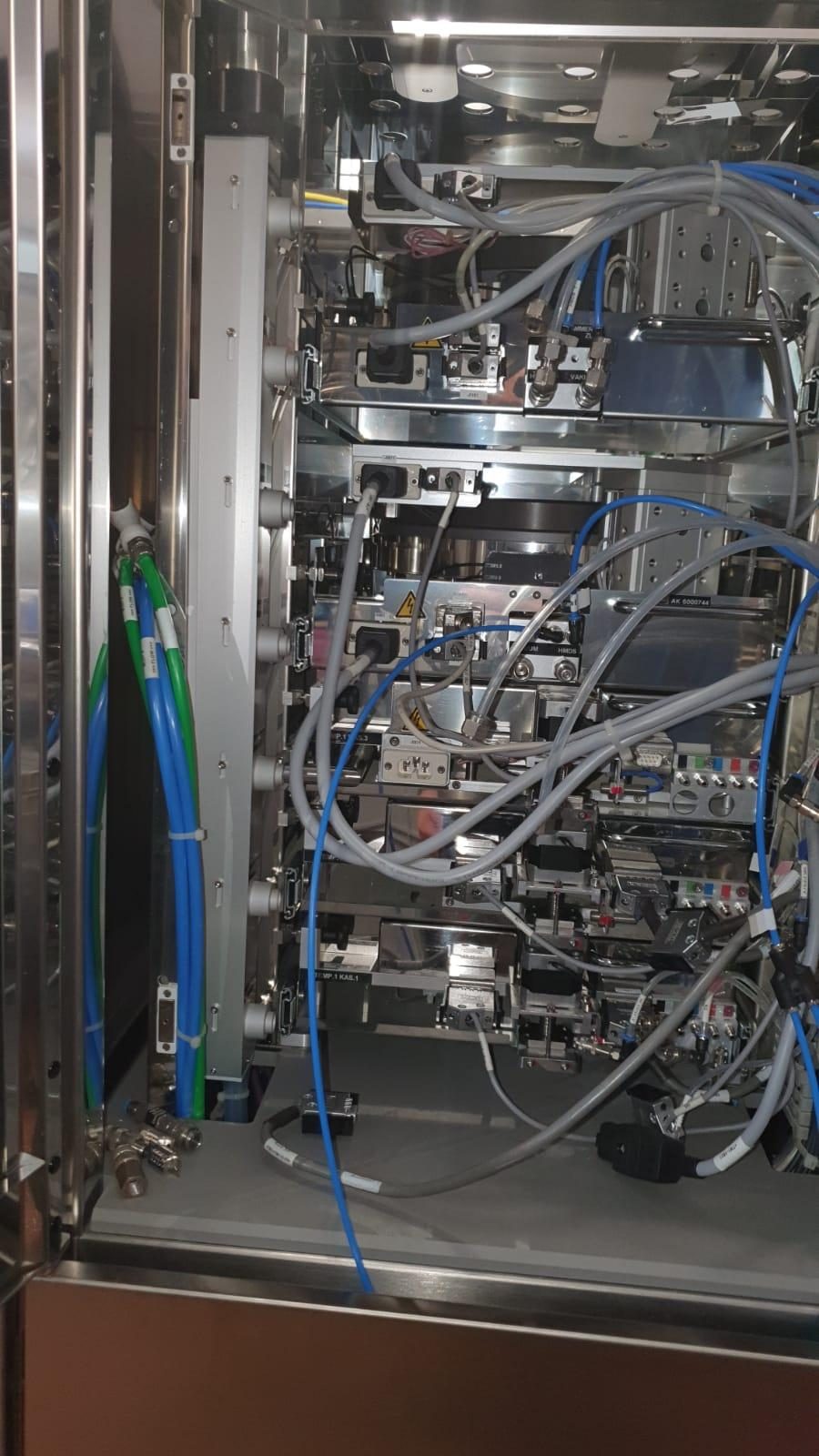

We have 1 Suss Gamma Cluster Coater-Developer Machine for immediate sale.

Installation, Service and Spare Parts are available.

The machine is fully functional and can be inspected on request. For further information please contact us.

We are selling here a Wafer Disco Mounter.

The Mounter is fully functional. Please contact us for further information.

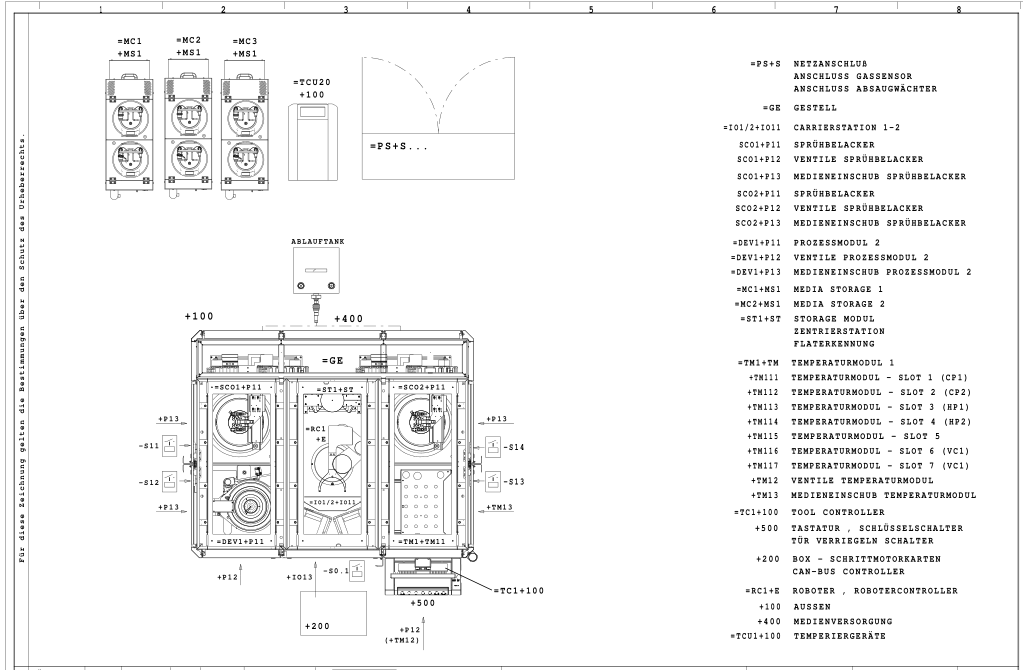

Manufacturer: Suss Microtec Year of manufacture: 2013 / 2014

Model: Suss Gamma Cluster System: Coater- Developer with Hotplates and Coolplates

Condition: Excellent, complete system, serviced during production period by Suss Microtec

working horse,

Wafer size: 6″ & 8″mm wafers.

Configuration: 4 Cassettes

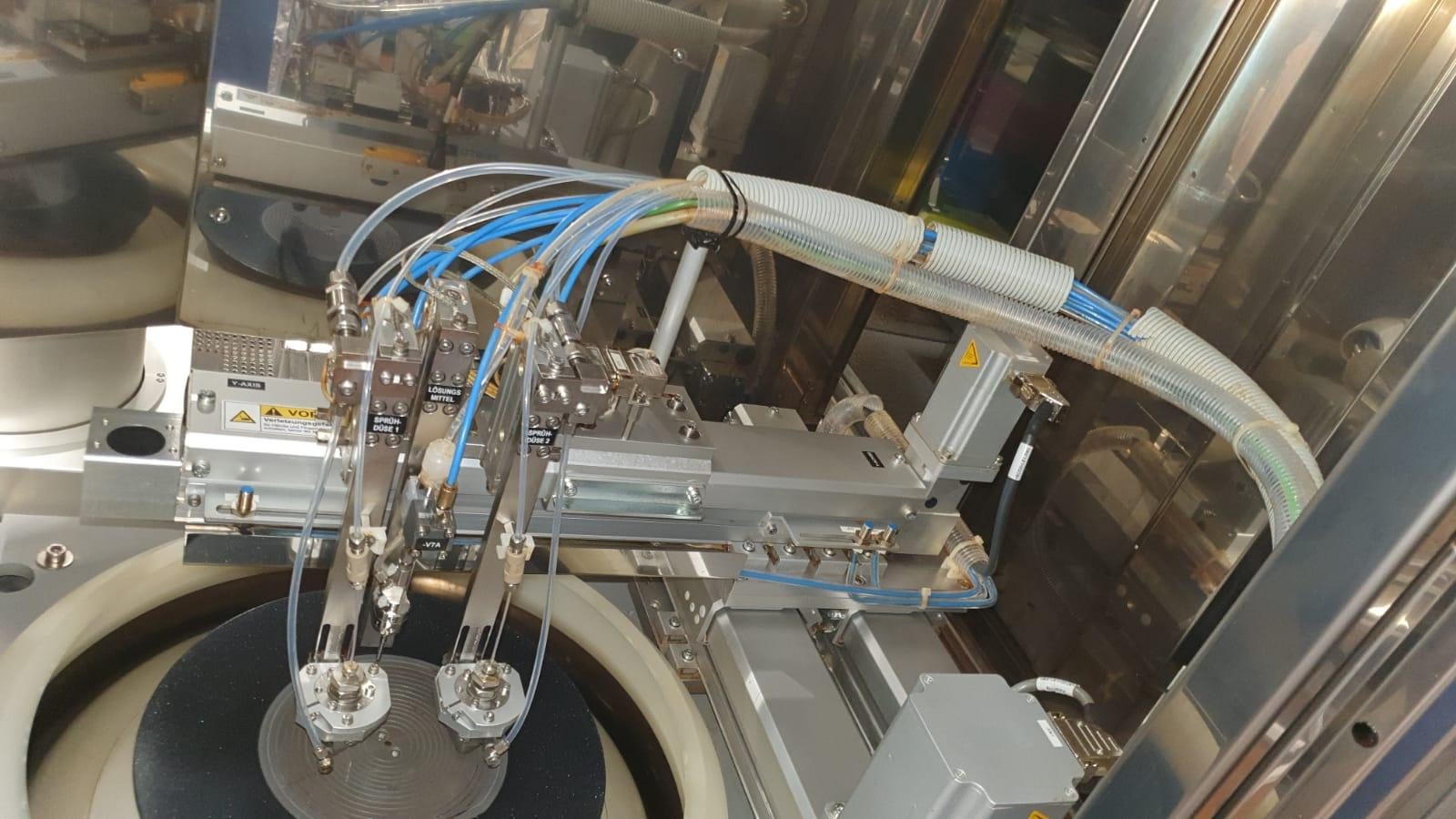

2 ea Spray Coat Stations / Note: The Spray Coat Stations can be upgraded to

Spin Coaters

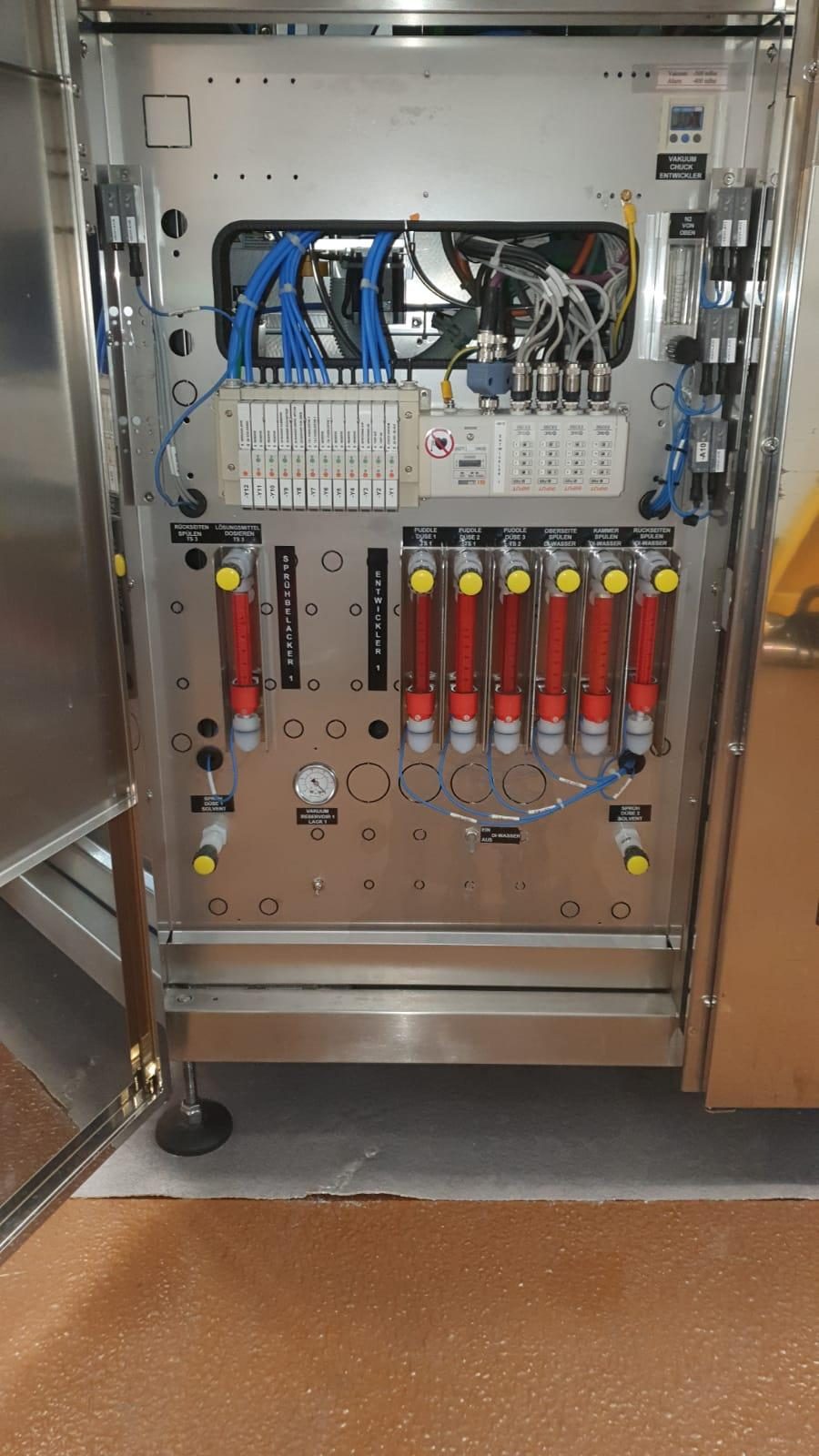

1 ea Developer Station

1ea Sankyo Wafer Handling Robot

1 ea Optical Centering Station

2 ea HMDS Hotplates 250 °C

1 ea Standard proximity Hotplate 250 °C & 2 ea Coolplates.

3 ea Media Cabinets with a total of 6 pressurized tanks

1 ea Electrical Cabinet

Options: If needed configuration of hotplates and coolplates can be modified to customer requirements.

Installation, Technical Support, spare parts and process support available.

The machine was in production from 2014 to early 2019. From 2019 until today the machine is used in our show room in Remseck Germany. 3 other Spray Coater – Developer Cluster Tools are available. Property of APEX Semiconductor GmbH.

Contact us when you need support for your aging none OEM supported equipment.

We have the spare parts, tools, and experiences to get the best value out of your investments.